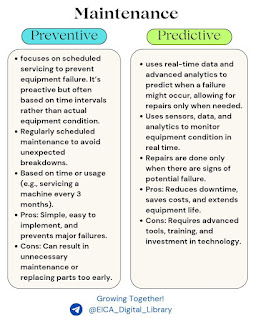

In the world of industrial maintenance, equipment reliability is everything. Two of the most popular maintenance strategies are Preventive Maintenance (PM) and Predictive Maintenance (PdM). While both aim to reduce downtime and improve lifespan.

What is Preventive Maintenance?

Preventive Maintenance involves regularly scheduled inspections, servicing, and part replacements based on time intervals or usage. The goal is to prevent equipment failure before it happens.

Key Features:

-

Time-based or usage-based scheduling

-

Routine tasks like lubrication, adjustments, and parts replacement

-

Reduces unexpected breakdowns

What is Predictive Maintenance?

Predictive Maintenance uses real-time data and condition-monitoring tools to predict when maintenance is needed. Instead of following a set schedule, maintenance actions are performed only when necessary.

Key Features:

-

Based on equipment condition (vibration analysis, thermo-graphy, etc.)

-

Requires sensors and data analysis

-

Focuses on actual wear and tear

-

More accurate and efficient

Conclusion

Both preventive and predictive maintenance play crucial roles in improving reliability and minimizing downtime. By understanding the strengths of each, you can design a maintenance strategy that keeps your operations running smoothly and cost-effectively.

0 Comments