A Programmable Logic Controller (PLC) is an industrial computer used to control manufacturing processes, machinery, or automation systems. PLCs are rigid for harsh environments and are programmed to perform logical, sequential, and timed operations.

Whether you're operating an assembly line or managing a water treatment plant, PLCs are behind the scenes making things work smoothly and automatically.

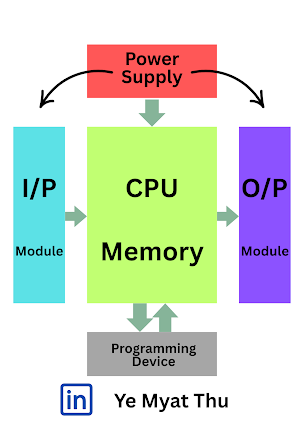

PLC Architecture

At the heart of every PLC lies its architecture. Here's how it's typically structured:

1. Central Processing Unit (CPU)

This is the brain of the PLC. It processes inputs, executes the control program, and sends output signals. The CPU includes memory for program storage and execution.

2. Input/Output (I/O) Modules

Input modules receive signals from sensors, switches, or buttons.

Output modules control devices like relays, valves, and Magnetic Contactor(MC).

3. Power Supply

Supplies the required DC power to the CPU and other components.

4. Programming Device

Engineers and technicians use a computer or handheld device to write and read the program into the PLC.

How a PLC Works

A PLC works in a loop called the scan cycle:

Read Inputs – Collect data from input devices.

Execute Program – Run logic instructions.

Update Outputs – Activate/deactivate output devices.

Repeat – Continually scan at millisecond speeds.

Common Brands

There are several well-known PLC brands that dominate the global market. Some of the most popular include:

Siemens (SIMATIC S7 Series)

Allen-Bradley (Rockwell Automation)

Mitsubishi Electric

Omron

Schneider Electric

Delta Electronics

Each brand has its software environment and features, but all operate on the same core principles.

Real-World Examples of PLCs in Action

1. Manufacturing Plants

In an automotive factory, PLCs control robotic arms, conveyor belts, and paint sprayers with precise timing and accuracy.

2. Food & Beverage Industry

PLCs are used for bottling, packaging, labeling, and quality inspection.

3. Water Treatment Plants

Automated valve operation, pump control, and chemical dosing are all managed by PLCs.

4. Building Automation

Control systems for elevators, lighting, HVAC, and security are built using PLCs.

Why Use PLCs?

Reliability: Designed for 24/7 operation in harsh environments.

Flexibility: Easily reprogrammed for different tasks.

Scalability: Can handle small machines or large systems.

Cost-Effective: Reduces manual labor and increases productivity.

Conclusion

PLCs are the backbone of modern industrial automation. From factories to power plants, they help ensure processes run efficiently, safely, and consistently. Whether you're an engineering student, technician, or automation enthusiast, understanding PLCs is a valuable step toward mastering the world of industrial control.

0 Comments